Be More Flexible: all things FIBERFLEX Printing Q and A

Having issues printing your FiberFlex? Let's fix that.

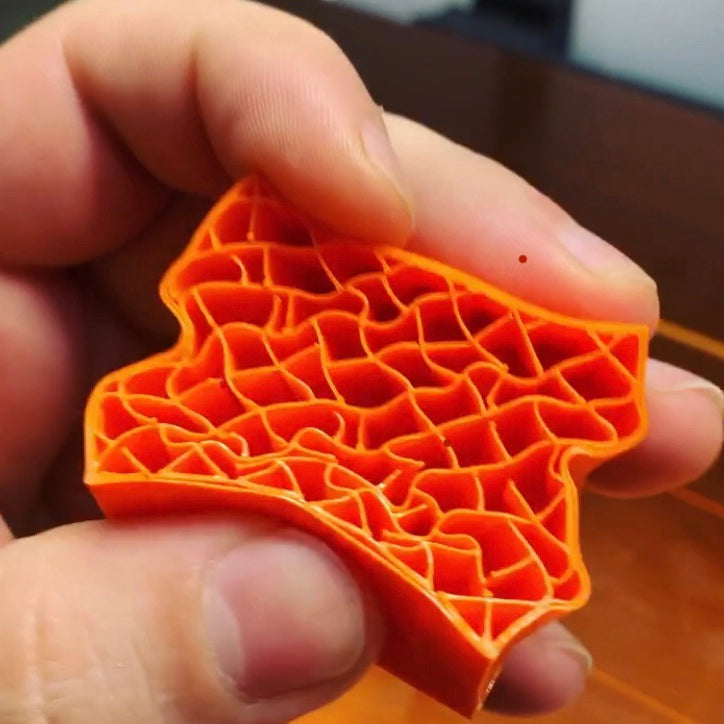

FiberFlex 30/40D are highly specialize materials well suited for even the most basic home printer settings. While it can take some tweaking, you can avoid some pitfalls by checking out what others have to share about printing with flexible materials.

Here are some of the questions we get asked most often about printing Fiberlogy FiberFlex 30D and FiberFlex 40D:

Q:

I have been having a hard time with the fiberflex. Mid print it stops extruding material i will have to play with it a little.

You guys have any tips ?

Thank you

Printing at 230 nozzle 60 build plate no retraction

A:

Hi and thank you for reaching out with your question. Let's dive in!

My first guess is that your fan settings may be too high, assuming your extruder is not slipping on the filament (that happens as well).

I would recommend printing a small test object (e.g. 40mm cube, 20mm high- whatever you would like to try) with the fan turned off with an overall uniform print speed of 20mm/sec (all print speeds) and see if you still have an issue.

With the 40d you may be able to run at 30mm/sec, but I wouldn’t push it.

Excess fan seemed to clog this filament for me if I remember correctly and I have often printed this filament without the fan on at all, or set it extremely low.

Q:

Hi Miriam, Wanted to follow up on the samples - they are as expected, excellent quality. :) I am having some trouble printing with the FiberFlex 40D - it does not want to adhere to the bed. I print on heated glass with either purple glue stick or hair spray for adhesion - are there recommendations for how to make this work better?

A:

Thank you so much for reaching out to us about the FiberFlex 40D. This is a long response but hopefully it will help get you better results:

We experienced similar if not identical issues in our quality testing. We did not use a glass bed for our tests, although what we did should work well in your case as well.

Regular PVA glue is *supposed* to work well on the glass bed for flexible material, however most of the printers we know that print this material on glass typically do not use *any* adhesive.

We tried many different adhesives, even Magigoo, but we found that the overall print did the best when it had adequate surface area holding the print itself to the bed.

We ultimately added ‘dog ears’ to our print (a phone case in this instance) and that did the trick. It gave the print more surface area to adhere to the bed and stopped it from popping off after only a few layers every single time.

We added them to the edge of the print with one layer so they came off super easy without much cleanup and did not affect the overall quality of the finished print. They typically pulled right off without leaving a jagged edge.

Hopefully what you are printing will allow for something like this or a brim would also work well. We used dog ears on our print mainly because it had 4 corners and made sense, but your project may be more well suited for an overall brim.

Once we made this change we did not need to use any adhesives, but again I would recommend a small test for the glass surface to see if some glue would help. I would be very curious to know if after adding a brim or dog ears to your print you still used the glue stick or if those changes sufficed.

If you still experience issues we recommend using an adhesive specifically designed for printing flexible material like Vision Miner or Magigoo.

Also, we found that successful prints come off the best if removed while the printing bed is still warm. When we waited and removed the print after several hours the print surface became rough and jagged from adhering to the printing bed.

This may be avoidable with the glass bed. Thank you for your question and let us know if you have any feedback to add to the discussion.