Key Features:

- Just like the standard Fiberlogy PP: Flexible and durable- prints designed with R PP (polypropylene) in mind can be some of the most durable prints achievable with todays materials

- The molecular structure and raw materials gives PP excellent adhesion between print layers when printing

- No fumes or odors- ideal for printing at home or small spaces where high levels of ventilation are not accessible

-

Non-toxic - Prints created with proper printing parameters can even withstand household dishwashers and sanitization cleaning cycles

- Engineered and created in Poland using highly specialized machinery and carefully selected raw materials

100% Recycled Eco Friendly Filament

To meet the challenges of a changing world and the pro-ecological expectations of 3D printing users, we have created Fiberlogy R. This filament is the fruit of our deep reflection and efforts. We focused on creating a product combining high quality, optimization of production processes and minimizing the negative impact on the ecosystem.

Fiberlogy R is a bold step on the way to making 3D printing technology more environmentally friendly. In its production, we use 100% recycled material. The raw material is carefully selected and derived only from verified sources, which helps to avoid potential filament contamination. The strict control of its acquisition and storage processes guarantees the highest quality of the final product that goes to our clients’ printers.

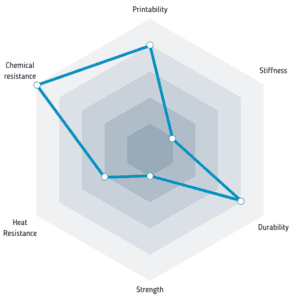

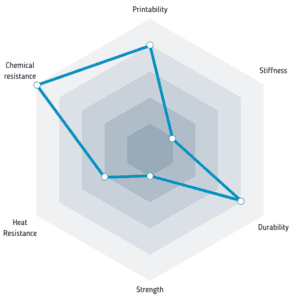

Strength and Flexibility

Polypropylene (PP) is one of the most commonly used polymers in industry. Its high flexibility, incredible durability, low weight and resistance to chemicals have meant that it has found countless applications from medicine, through the automotive industry to the packaging industry.

Fiberlogy PP filament has tapped the potential of this incredible material and made it possible to use in 3D printing.

The impressive tensile strength makes polypropylene perfect for producing elements that require durability while maintaining flexibility such as lockable containers, handles, etc. It is successfully used in both advanced engineering projects and at home.

Polypropylene is recyclable, which is why printouts and printer scrap can be segregated with other garbage and recycled, which perfectly reflects the spirit of the idea of “zero-waste”.

Printing Ideas and Applications:

- Daily Use Items: boxes with closures, hangers, handles, fasteners, watch straps

- Motorizations: bumpers, covers

- Toys: figurines, cars / car parts, drones

- Kitchen Articles: food containers, dishes, cups, etc.

- Medicine: test tubes, laboratory vessels

How to print:

Printing temperature: 220 – 250°C (we recommend starting at the higher end at 250C)

Bed temperature: 70-80°C

Closed Chamber: not required

Fan: 0-50% (we recommend 0% fan to start)

Flowrate: 100-105%

Printing Speed: < 45mm/s

Surface: packing tape (most cost effective for testing, however, it becomes permanently attached to the print) , Vision Minor, Magigoo for Polypropylene

Retraction (direct): 2-3mm

Retraction (bowden): 4-6mm

Retraction Speed: 20-45mm/s

Notes: We *strongly* recommend the use of a bed adhesive when printing with polypropylene. Packing tape is the most economical adhesive option to start off using.

You can find more detailed recommended print settings for all Fiberlogy Filaments in this article.

TDS and MSDS:

Net weight : 0.75 kg

All of our materials have outstanding properties and parameters - diameter tolerance of +/- 0.02mm and oval tolerance of +0.01mm.